The GENTEC line of CNC cutting systems are designed to be a reliable, cost-effective, and meet your high performance cutting requirements. The Master CNC cutting series is built to ensure a smooth and accurate performance. It is equipped with a PC base CNC control, AC servo drive, precision linear guide waysand self aligning plasma torch collision device, etc. GENTEC provides a broad choice of options that allow you to configure your CNC cutting system with the capacities, speed and accuracy to meet your needs.

Advanced Technology

The cross axis is a high precision rack & pinion drive.

• Self aligning plasma torch with collision shutdown

• Plasma sensor THC uses precise linear way for high accuracy positioning. This low maintenance unit is dustproof and quiet

• Motorized torch holder is manufactured with durable aluminum body and equipped with a precision spline-shaft. It achieves rapid torch positioning. The high temperature protective cover is waterproof and dustproof

• Accurate high speed powder marking unit for precision line making

• Dual linear way design for cross drive provides low noise and precise motion at high speed

• The CNC controller features a Windows XP operating system and colored LCD screen. The multi-axis controller base incorporates flexibility along with easy access

• Precision ground track pre-mounted to structural H beam

Features

• Low profile, rigid gantry structure

• The brushless AC servo motors produce high torque with high inertia and accurate resolution

• Precision worm gear reducers with backlash less than 2 arc minutes

• Position accuracy: +/-0.004"; Repeat accuracy: +/-0.004"

• Flexible cable-chain hose and cable conveyors in both axis

• The carriage is equipped with pre-loaded guide blocks for precise linear motion

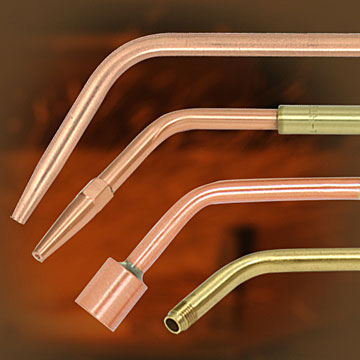

• Optional preheat and individual torch solenoid valve is available

• Self lubricating main rail is standard

• Optional patented dust prevention device on cross axis prevents dust entering the linear ways

• Trouble-free torch holder with fine adjustment settings (Forward- Reverse and Tilt angle) provides long service life

• All cutting solenoids valves and pressure regulators are mounted in a central cabinet conveniently installed to the machine frame. The cutting control with Hi/Low preheat and auto ignition is designed to work with all torches at their maximum pressure and flow rates

| Model | Unit | Master 20s/20 | Master 25s/25 | Master 30s/30 | Master 35s/35 | Master 40s/40 | Master 50 | Master 60 | Master 70 | Master 80 |

| POWER INPUT** | - | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V |

| RAIL GAUGE (B)*** | in | 78 | 98 | 118 | 137 | 157 | 196 | 236 | 275 | 324 |

| MAX. CUTTING WIDTH (A) | in | 62 | 82 | 102 | 122 | 141 | 181 | 220 | 259 | 299 |

| MAX. TORCH STROKE ON CROSS AXIS (E) | in | 78 | 97 | 118 | 137 | 157 | 196 | 236 | 275 | 324 |

| MAX. TRAVEL SPEED | in/min | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 630 Dual, (945 optional) | 630 Dual, (945 optional) | 470 Dual, (945 optional) | 470 Dual, (945 optional) |

| CUTTING SPEED | in/min | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 470 Dual, (945 optional) | 470 Dual, (945 optional) | 314 Dual, (470 optional) | 314 Dual, (470 optional) |

| MIN. CUTTING WIDTH (F) | in | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| LONGITUDINAL DRIVE | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on dual side | Rack & pinion drive on dual side | Rack & pinion drive on dual side | Rack & pinion drive on dual side | |

| CROSS DIRECTION DRIVE | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | |

| LONGITUDINAL RAIL | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | |

| CROSS DIRECTION RAIL | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | |

| OVERALL RAIL LENGTH | in | 118 | 118 | 118 | 118 | 118 | 118 | 118 | 118 | 118 |

| OVERALL WIDTH (C) | in | 120 | 140 | 160 | 180 | 200 | 238 | 276 | 315 | 355 |

| OVERALL HEIGHT (D) | in | 67 | 67 | 71 | 71 | 71 | 73 | 73 | 75 | 75 |

| PARKING SPACE | in | 50 | 50 | 60 | 60 | 60 | 72 | 72 | 84 | 84 |

| OVERALL DEPTH | in | 60 | 60 | 69 | 69 | 69 | 81 | 81 | 93 | 93 |

| WEIGHT | lb | 2712 | 2811 | 3263 | 3396 | 3528 | 4631 | 4851 | 5292 | 5623 |

| * Master 20s/25s/30s/35s/40s are single drives on a longitudinal axis ** Other power inputs available *** Special or large rail gauge are also available |