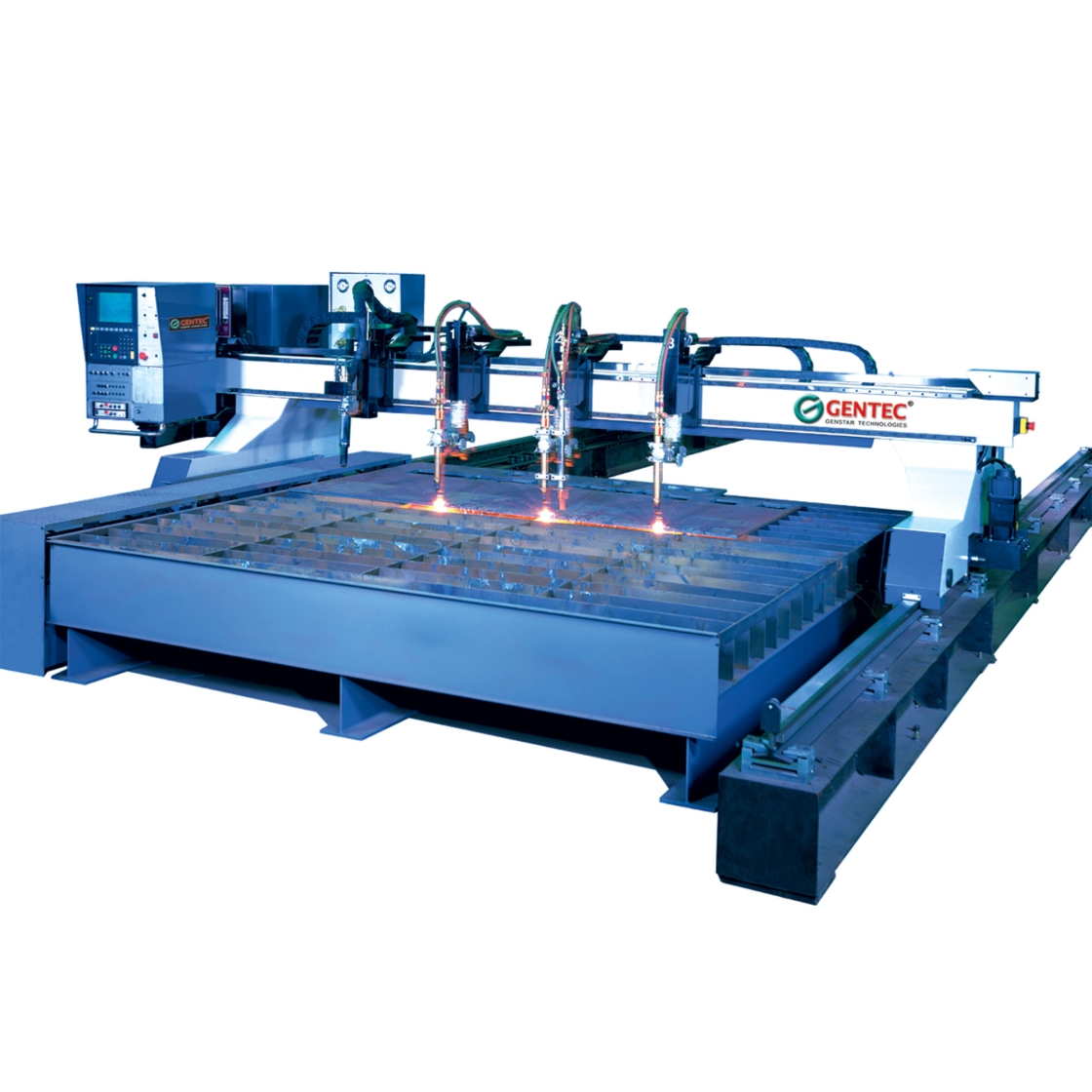

Cutting Automation

The GENTEC line of CNC cutting systems are designed to be a reliable, cost-effective, and meet your high performance cutting requirements. The Master CNC cutting series is built to ensure a smooth and accurate performance. It is equipped with a PC base CNC control, AC servo drive, precision linear guide waysand self aligning plasma torch collision device, etc. GENTEC provides a broad choice of options that allow you to configure your CNC cutting system with the capacities, speed and accuracy to meet your needs.

Advanced Technology

The cross axis is a high precision rack & pinion drive.

• Self aligning plasma torch with collision shutdown

• Plasma sensor THC uses precise linear way for high accuracy positioning. This low maintenance unit is dustproof and quiet

• Motorized torch holder is manufactured with durable aluminum body and equipped with a precision spline-shaft. It achieves rapid torch positioning. The high temperature protective cover is waterproof and dustproof

• Accurate high speed powder marking unit for precision line making

• Dual linear way design for cross drive provides low noise and precise motion at high speed

• The CNC controller features a Windows XP operating system and colored LCD screen. The multi-axis controller base incorporates flexibility along with easy access

• Precision ground track pre-mounted to structural H beam

Features

• Low profile, rigid gantry structure

• The brushless AC servo motors produce high torque with high inertia and accurate resolution

• Precision worm gear reducers with backlash less than 2 arc minutes

• Position accuracy: +/-0.004"; Repeat accuracy: +/-0.004"

• Flexible cable-chain hose and cable conveyors in both axis

• The carriage is equipped with pre-loaded guide blocks for precise linear motion

• Optional preheat and individual torch solenoid valve is available

• Self lubricating main rail is standard

• Optional patented dust prevention device on cross axis prevents dust entering the linear ways

• Trouble-free torch holder with fine adjustment settings (Forward- Reverse and Tilt angle) provides long service life

• All cutting solenoids valves and pressure regulators are mounted in a central cabinet conveniently installed to the machine frame. The cutting control with Hi/Low preheat and auto ignition is designed to work with all torches at their maximum pressure and flow rates

Inquire about this product

Contact Us

Hours

Phone

Fax

Address

Chino, CA 91710, USA

Ordering Info

| Model | Unit | Master 20s/20 | Master 25s/25 | Master 30s/30 | Master 35s/35 | Master 40s/40 | Master 50 | Master 60 | Master 70 | Master 80 |

| POWER INPUT** | - | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V | 3 Phase 230/460V |

| RAIL GAUGE (B)*** | in | 78 | 98 | 118 | 137 | 157 | 196 | 236 | 275 | 324 |

| MAX. CUTTING WIDTH (A) | in | 62 | 82 | 102 | 122 | 141 | 181 | 220 | 259 | 299 |

| MAX. TORCH STROKE ON CROSS AXIS (E) | in | 78 | 97 | 118 | 137 | 157 | 196 | 236 | 275 | 324 |

| MAX. TRAVEL SPEED | in/min | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 470 Single/630 Dual, (945 optional) | 630 Dual, (945 optional) | 630 Dual, (945 optional) | 470 Dual, (945 optional) | 470 Dual, (945 optional) |

| CUTTING SPEED | in/min | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 314 Single/470 Dual, (630 optional) | 470 Dual, (945 optional) | 470 Dual, (945 optional) | 314 Dual, (470 optional) | 314 Dual, (470 optional) |

| MIN. CUTTING WIDTH (F) | in | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| LONGITUDINAL DRIVE | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on single side /dual side | Rack & pinion drive on dual side | Rack & pinion drive on dual side | Rack & pinion drive on dual side | Rack & pinion drive on dual side | |

| CROSS DIRECTION DRIVE | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | Unique bell drive or Rack & pinion drive | |

| LONGITUDINAL RAIL | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | Ground I-rail | |

| CROSS DIRECTION RAIL | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | Double linear way | |

| OVERALL RAIL LENGTH | in | 118 | 118 | 118 | 118 | 118 | 118 | 118 | 118 | 118 |

| OVERALL WIDTH (C) | in | 120 | 140 | 160 | 180 | 200 | 238 | 276 | 315 | 355 |

| OVERALL HEIGHT (D) | in | 67 | 67 | 71 | 71 | 71 | 73 | 73 | 75 | 75 |

| PARKING SPACE | in | 50 | 50 | 60 | 60 | 60 | 72 | 72 | 84 | 84 |

| OVERALL DEPTH | in | 60 | 60 | 69 | 69 | 69 | 81 | 81 | 93 | 93 |

| WEIGHT | lb | 2712 | 2811 | 3263 | 3396 | 3528 | 4631 | 4851 | 5292 | 5623 |

| * Master 20s/25s/30s/35s/40s are single drives on a longitudinal axis ** Other power inputs available *** Special or large rail gauge are also available |

Restrictions